Installation Guide

Aluminium Venetian Blinds

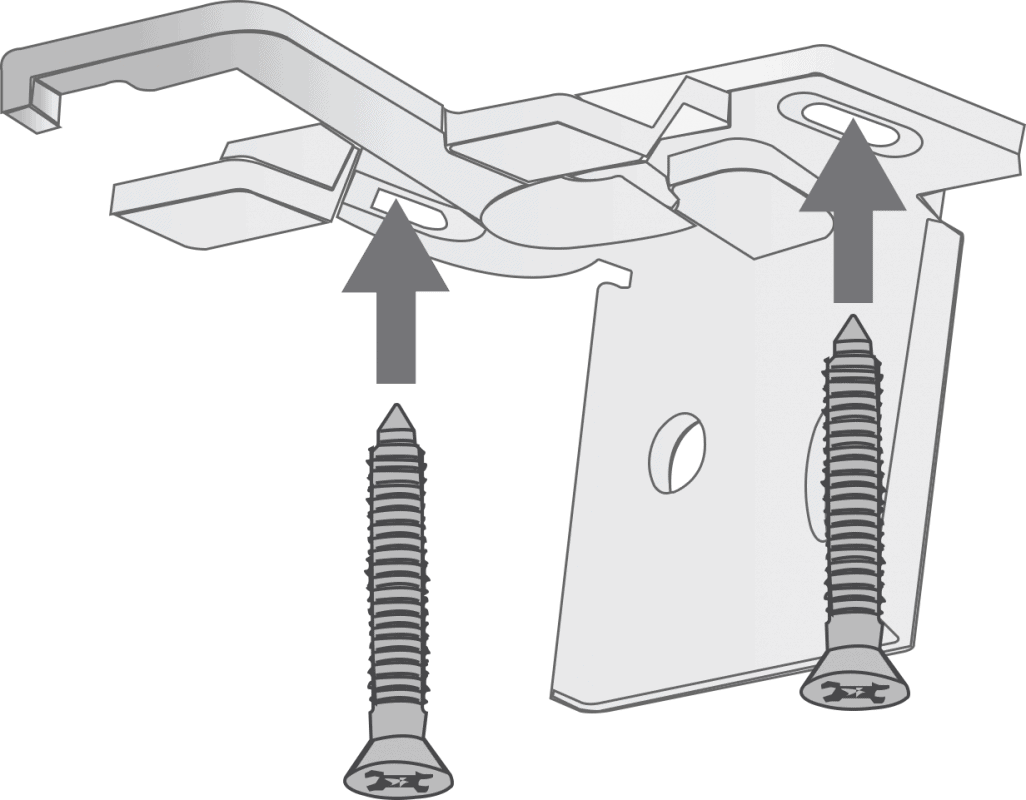

Fitting the brackets Step 1

The brackets offer two methods of installation:

Top-Fixing

Where the brackets are screwed into the lintel (or ‘ceiling’ of the recess)

Face-Fixing

Where the brackets are screwed onto a facing surface (a wall or window frame)

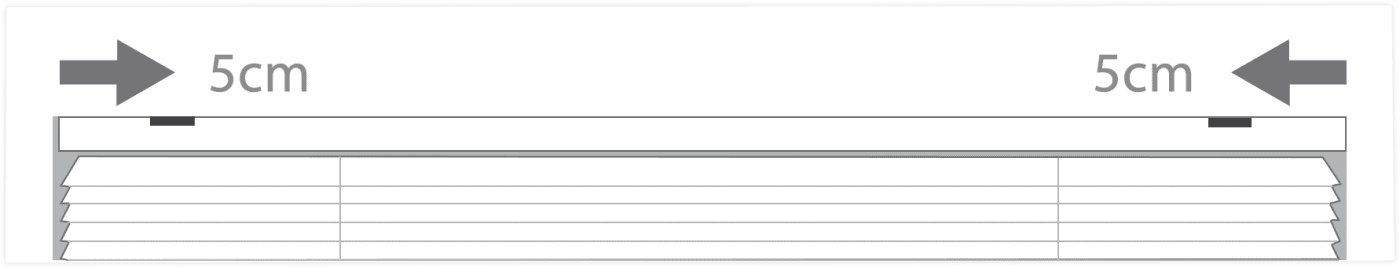

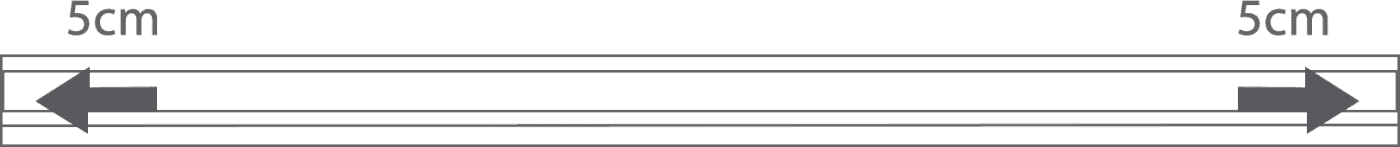

The outermost brackets should be mounted at least 5cm in from the ends of the blind.

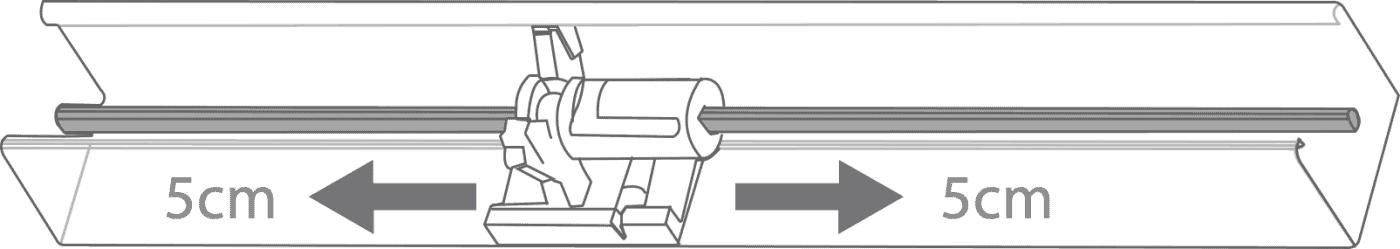

The remainder of the brackets should be spaced evenly along the width of the blind, ensuring that they do not interfere with any of the moving components in the headrail.

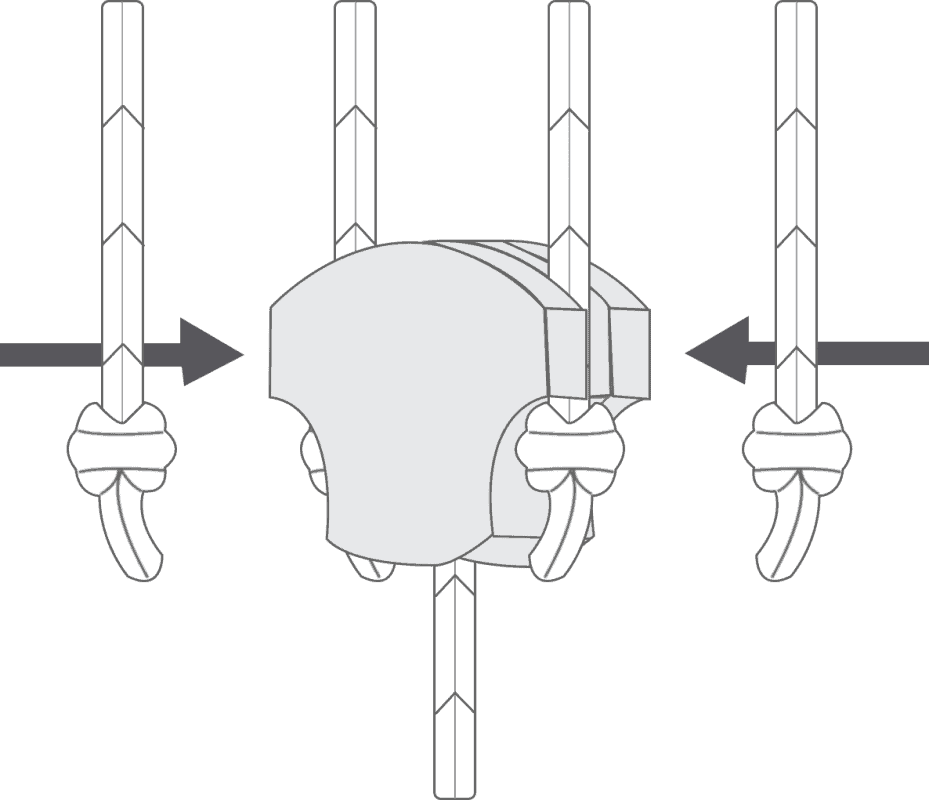

Fitting the blind Step 2

Hook the front lip of the headrail over the protruding hooks at the front of the bracket, then raise the back of the headrail so that it’s level. Holding it in this position, swing the swing-arm over and press it firmly against the headrail to lock it in place.

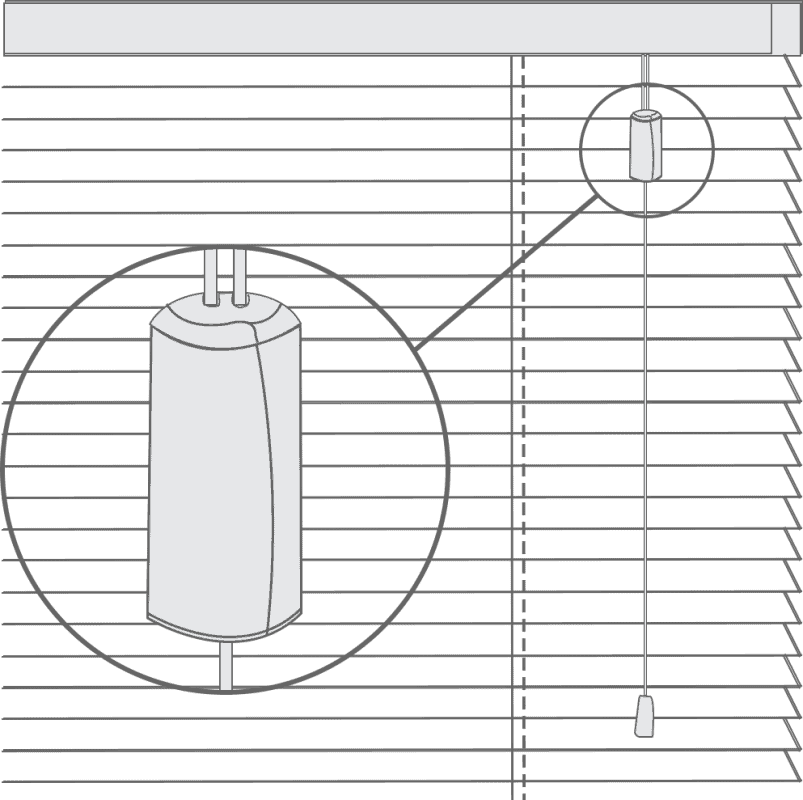

Child Safety Step 3

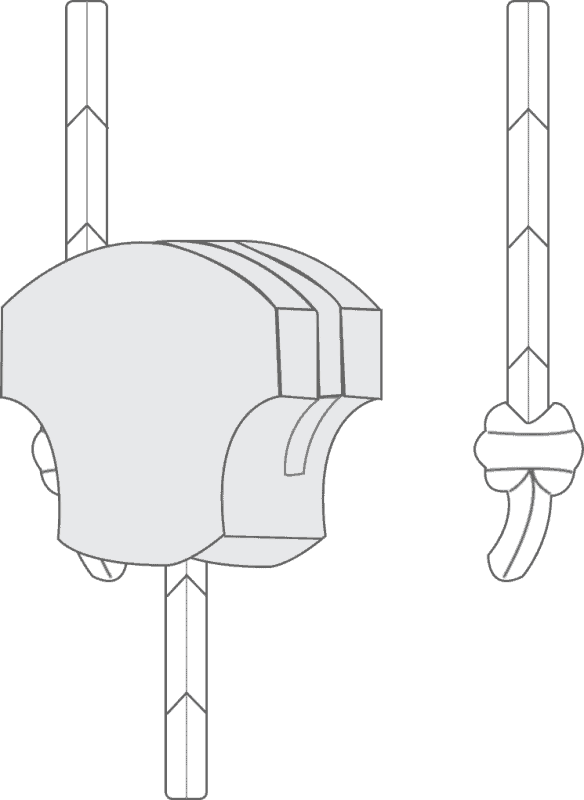

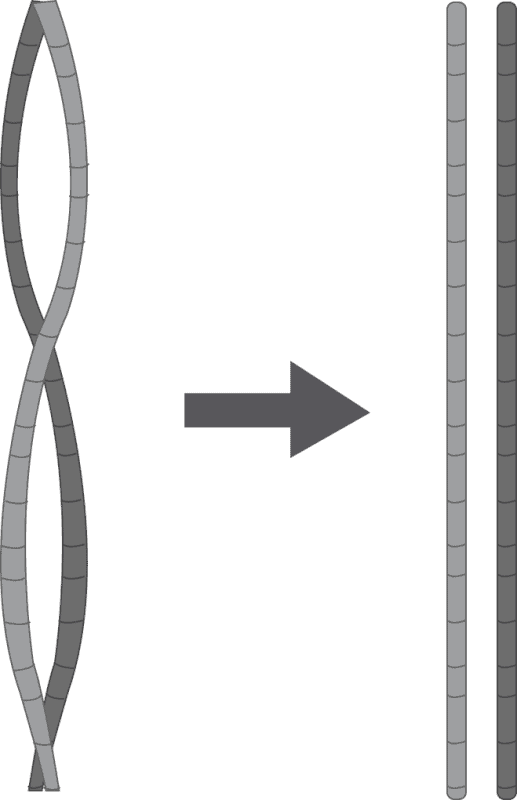

Cord

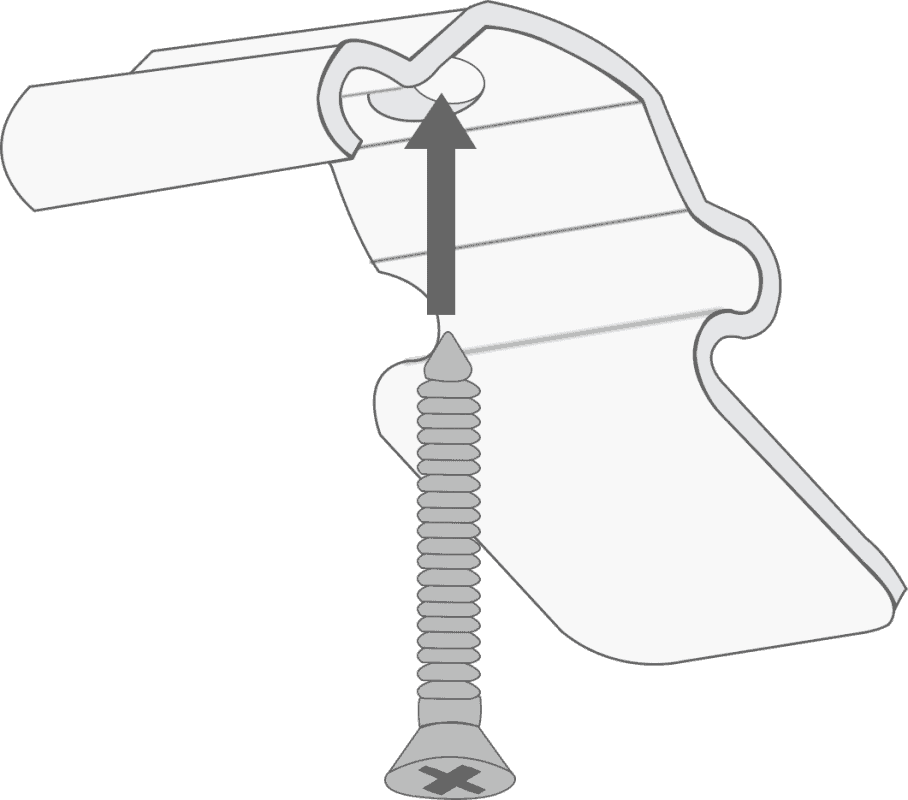

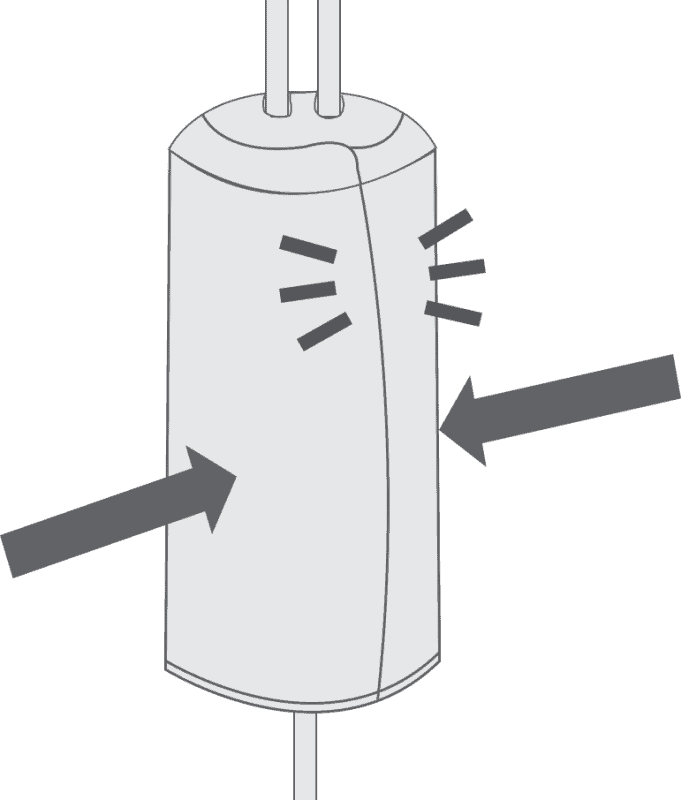

A breakaway cord condenser is pre-fitted to the lift cords so that when a horizontal force is applied to the cords entering the condenser, it safely releases the cords to eliminate any hazardous loops.

If any of the cords are pulled from the condenser…

Make sure the cords aren’t twisted or tangled

Then slot the cords into the notches on the sides of the condenser, ensuring the knots at the ends of the cords are tight.

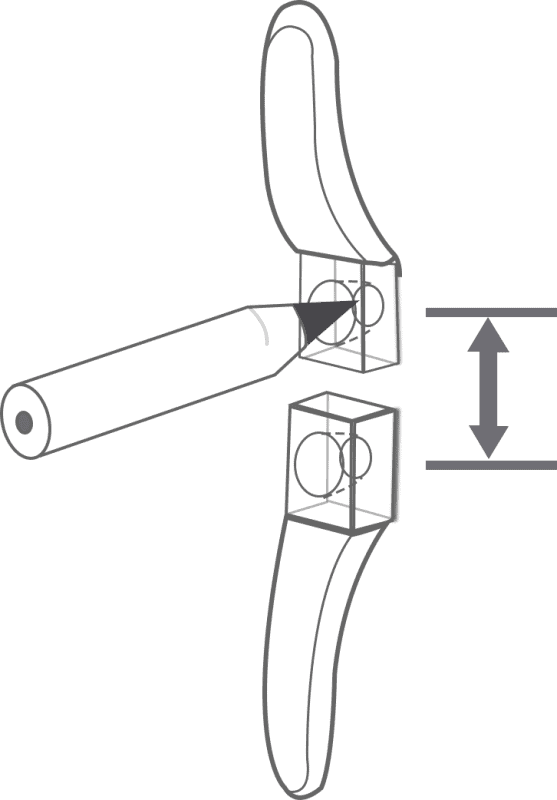

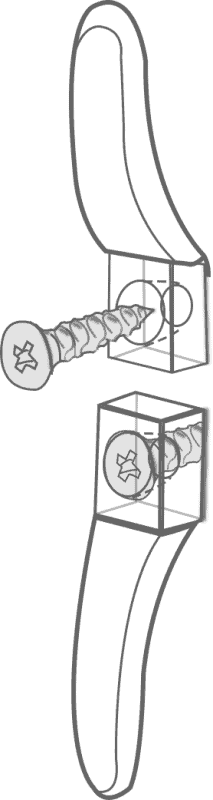

Cord Safety Cleat

The safety cleat shall be installed as close to the headrail as possible and in all cases not less than 1500mm from the floor. The cord must be fully accumulated around the safety cleat(s) when the blind is not in use. Use the table below to determine the distance required between the cleats to fully accumulate the cords when the blind is fully raised.

| Drop of blind | *Distance between cord cleats(centre to centre) |

|---|---|

| 1-1000mm | 100mm |

| 1001-2000mm | 150mm |

| 2001-3000mm | 300mm |

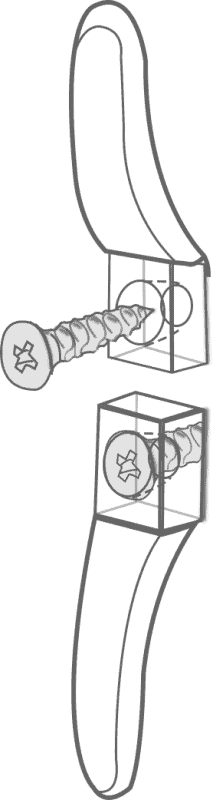

Place the safety cleat in the desired position on the wall and mark the positions of the holes with a pencil.

*Distance between cord cleats

(centre to centre)

Mark the hole positions and drill as required. Use the screws provided to attach the safety cleat to the wall.

Wrap the cords around the cord cleats in a figure of 8. When the cords are fully accumulated, ensure they are secure so that when any cord is pulled, no excess cord is released.

Additional Items

Hold Down Brackets

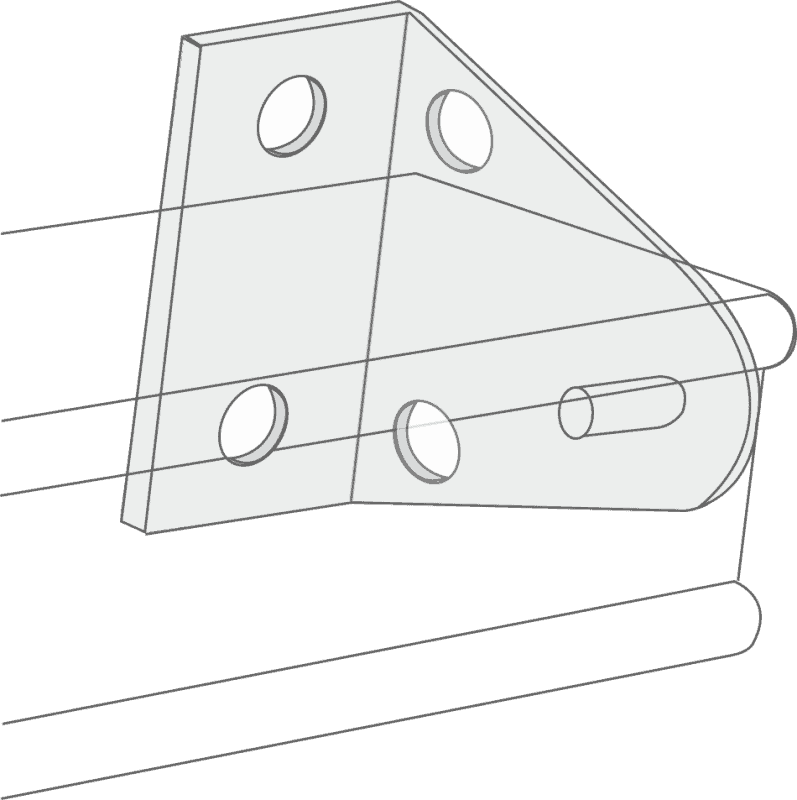

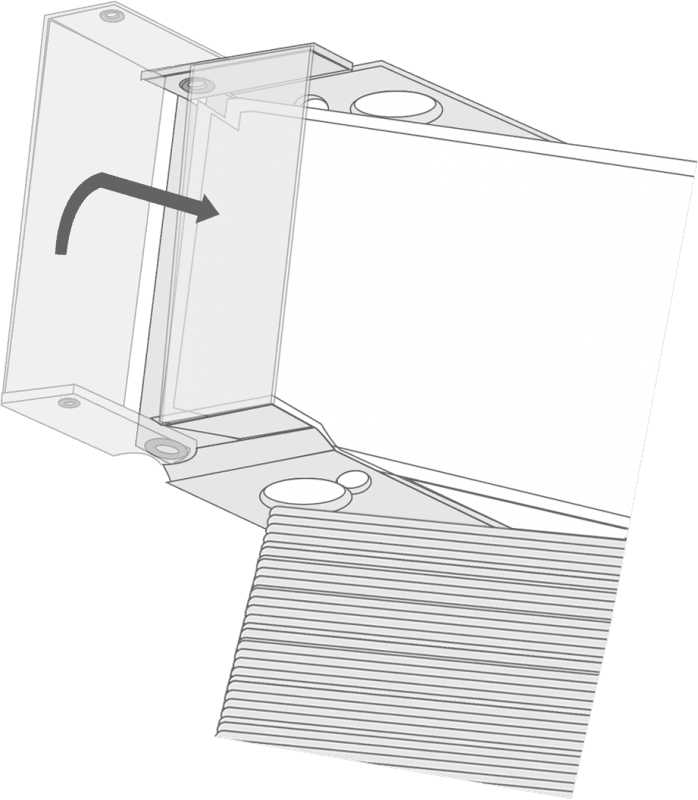

Two triangular, transparent brackets are supplied, which are used to hold the bottom of the blind against the fitting surface. These are only recommended for use when fitting the blind to a door, they are not usually required for window installations.

Installation Guide

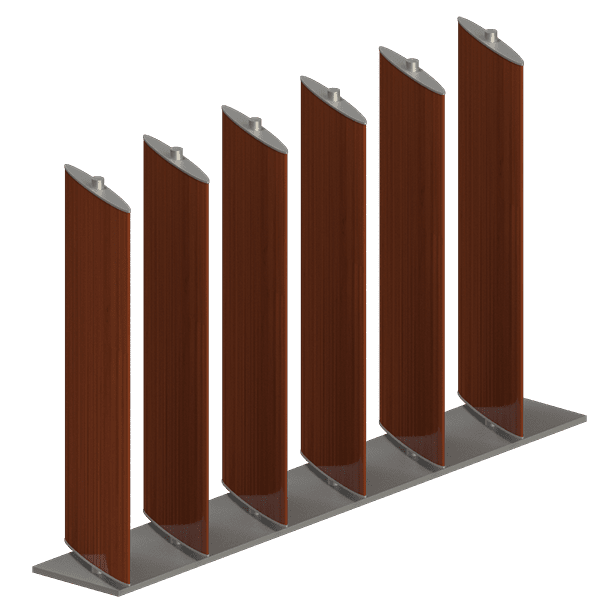

Vertical Blinds

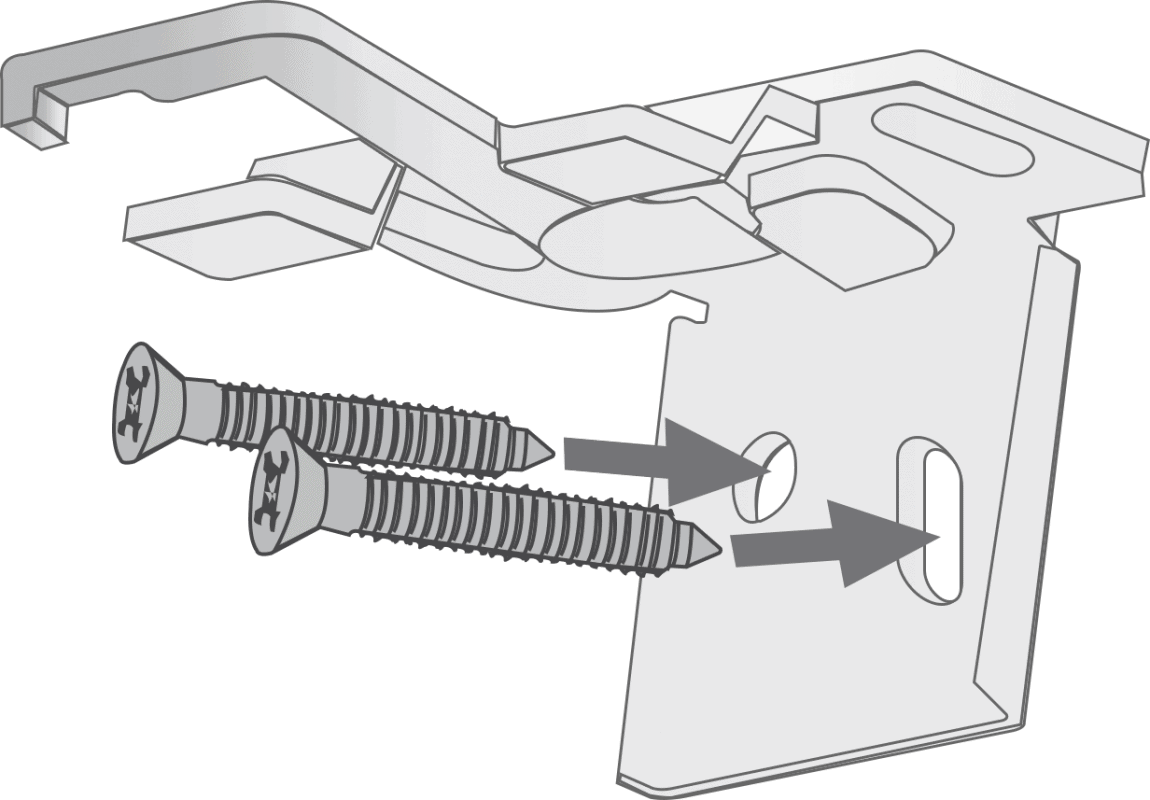

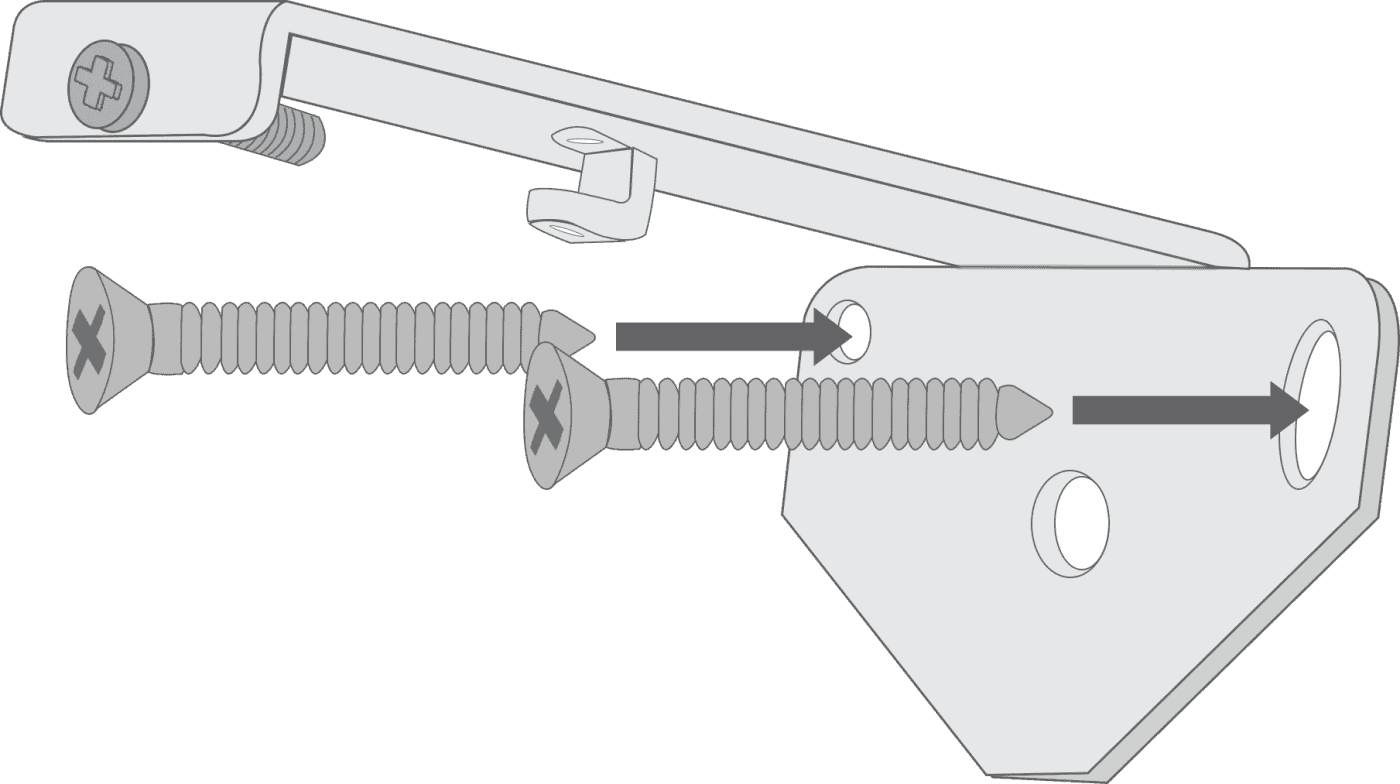

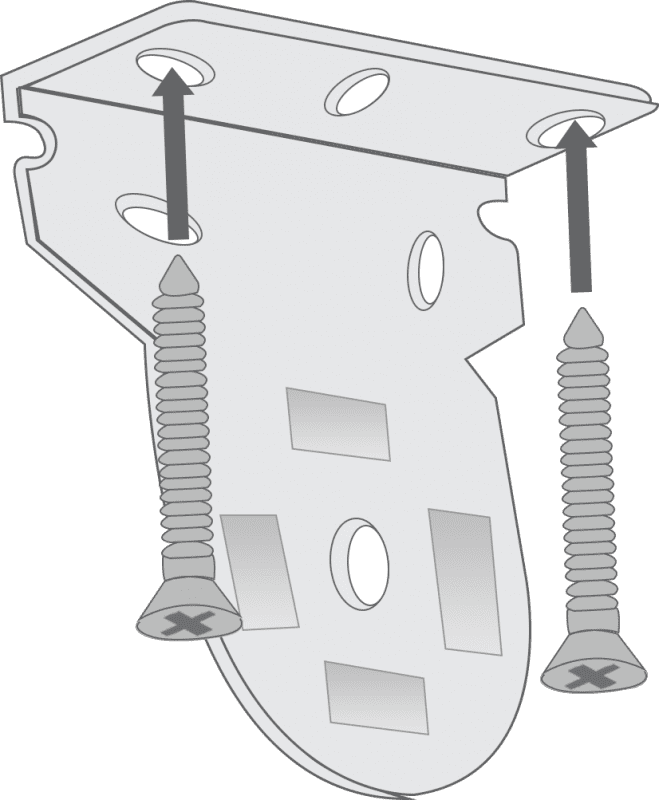

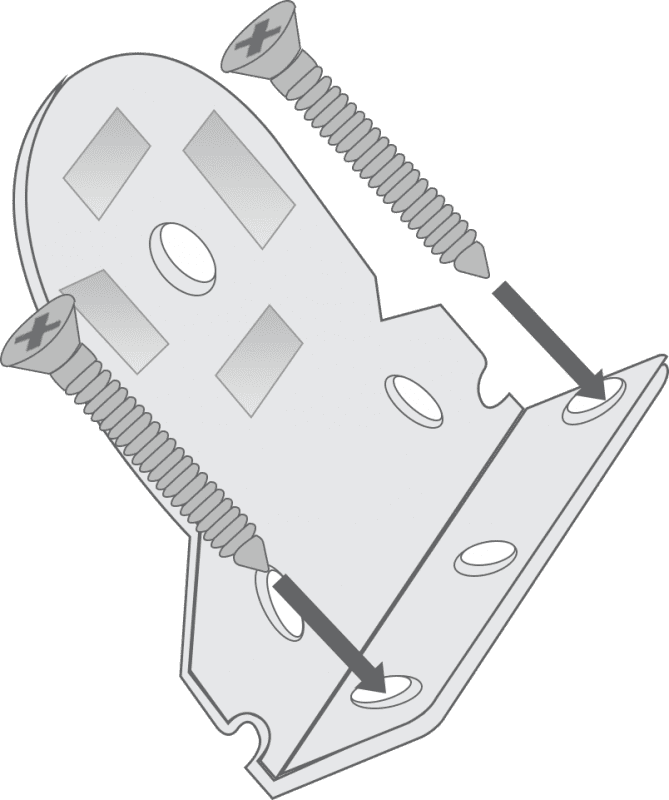

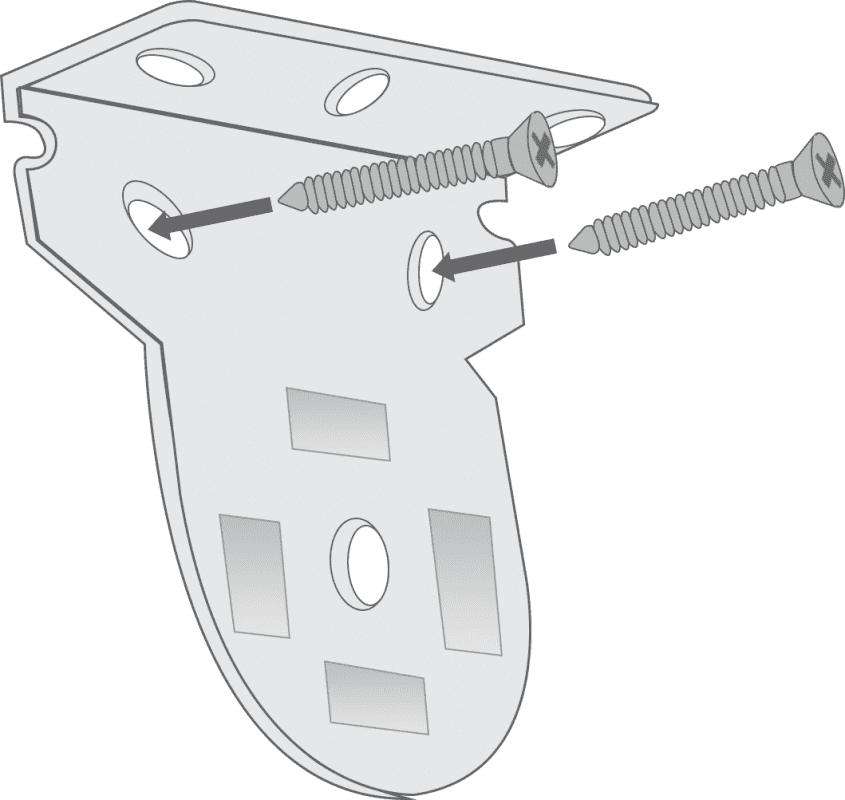

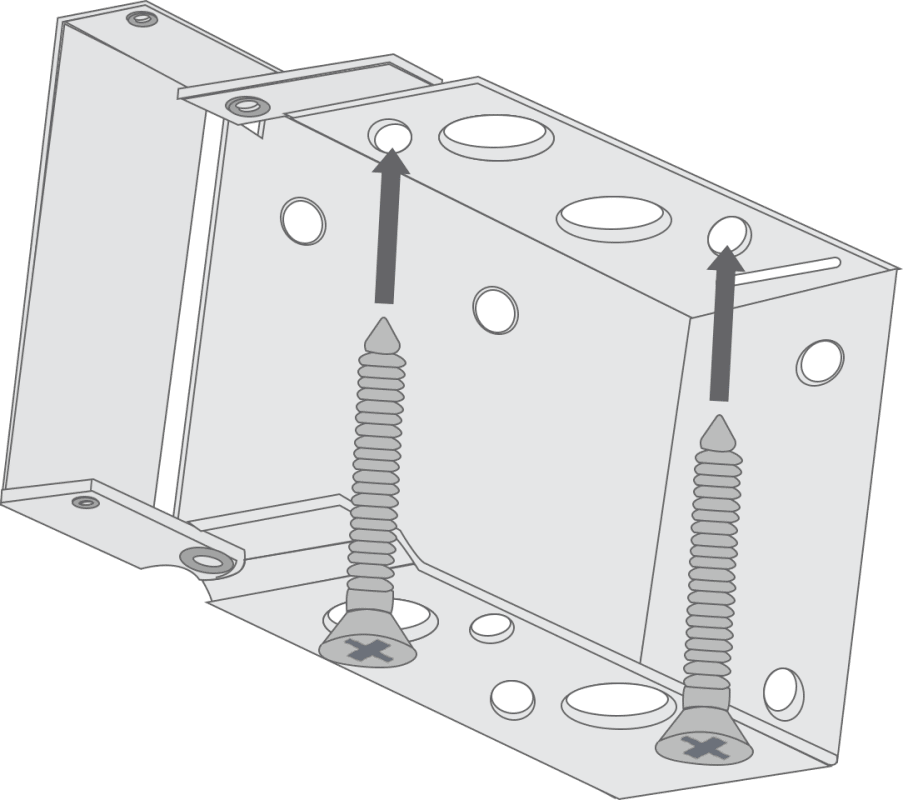

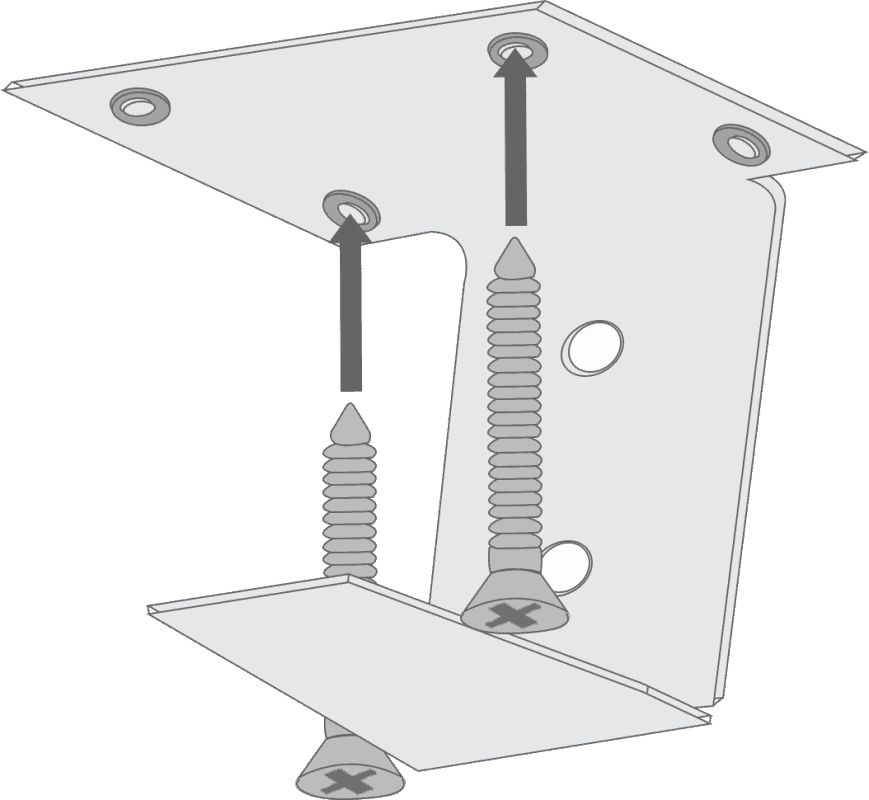

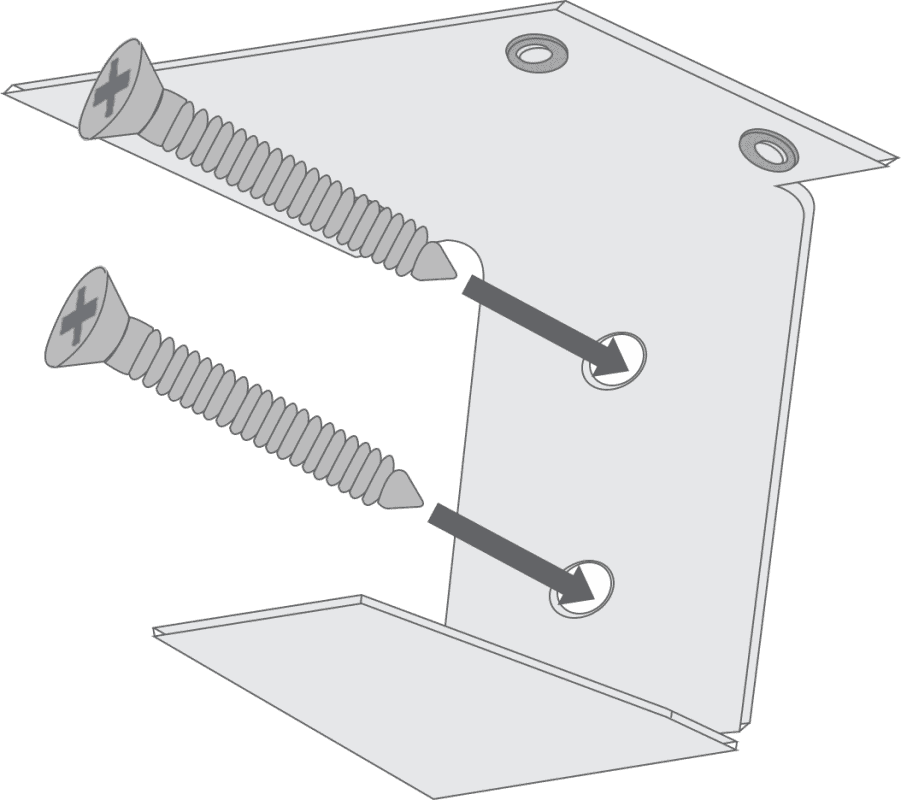

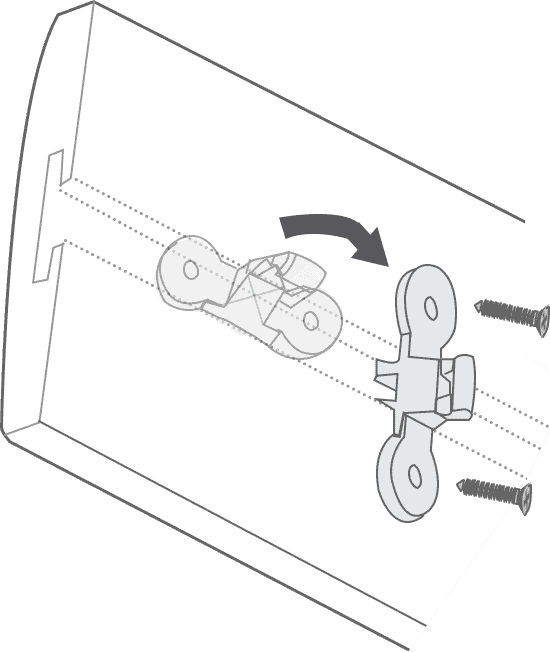

Fitting the brackets Step 1

There are two types of brackets for vertical blinds, each of which offers a different method of installation:

Top-Fixing

Use the single hole in the top of the bracket to fix to

the lintel (the ‘ceiling’ of the recess).

Face-Fixing

Use two screws through the back plate to mount

onto a facing surface (a wall or window frame)

Note that the position of the outermost brackets should be

at least 5cm away from the ends of the rail, with any other

brackets evenly distributed across the width

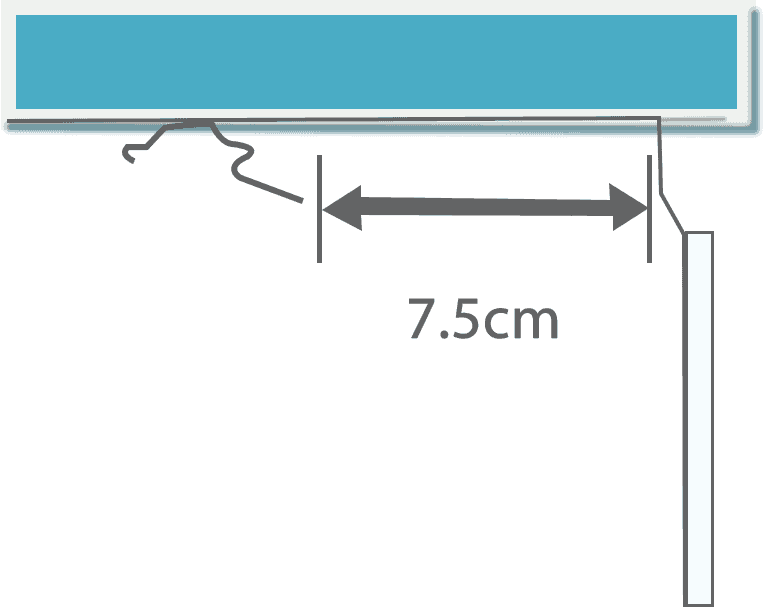

If you’re using top-fix brackets, make sure that you mount them at least 7.5cm in front of either the window frame, or any protruding vents or handes, if there are any. This allows space for the louvres to turn open and closed.

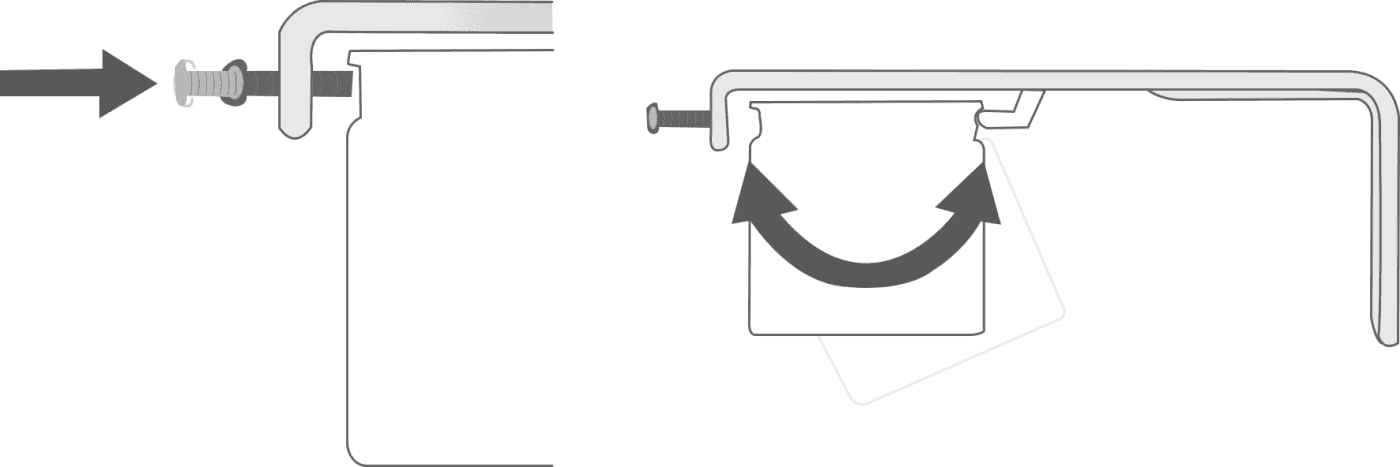

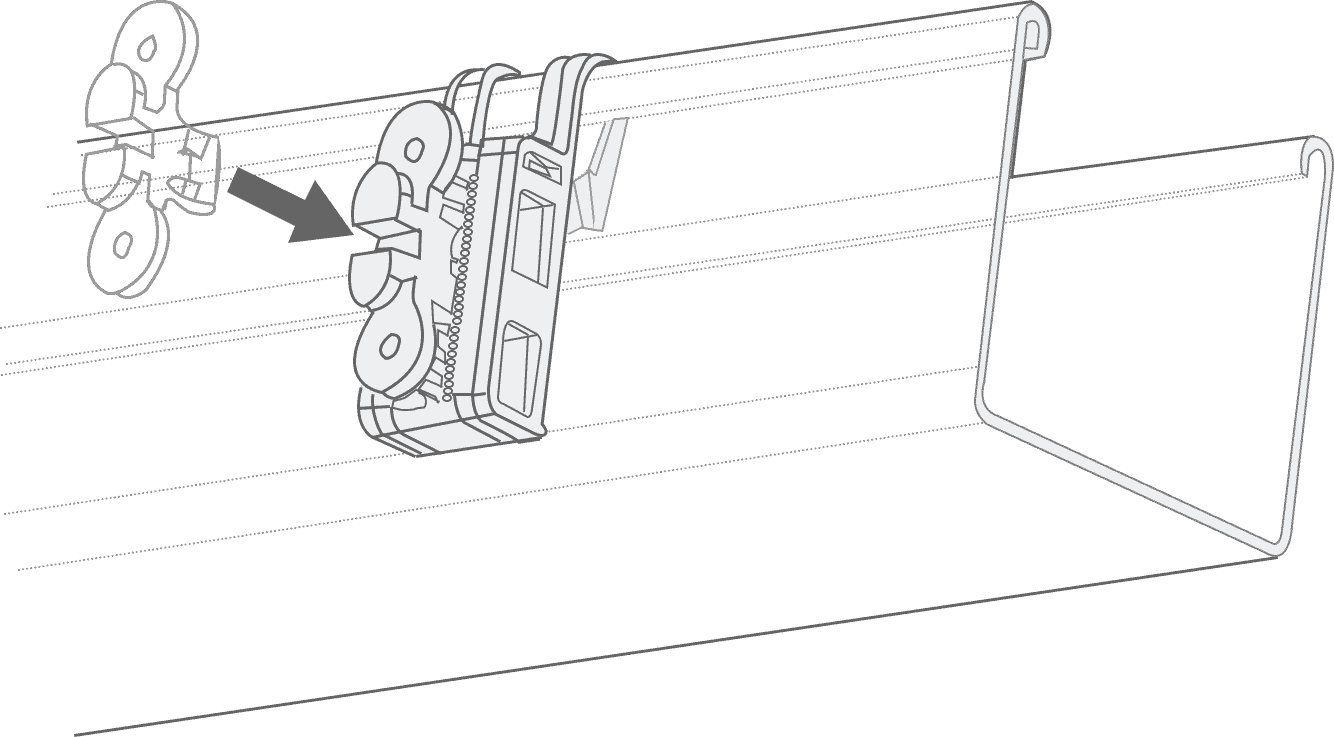

Fitting the blind Step 2

Top-Fixing

Situate the front lip of the headrail into the front of the

bracket.

Lift the back of the headrail and push up firmly to secure

the back of the rail into the bracket.

Face-Fixing

Situate the back lip of the headrail into the back hook of

the bracket.

Lift the front of the headrail so it’s level, then tighten the

screw in the front of the bracket to secure the rail in place

Child Safety Step 3

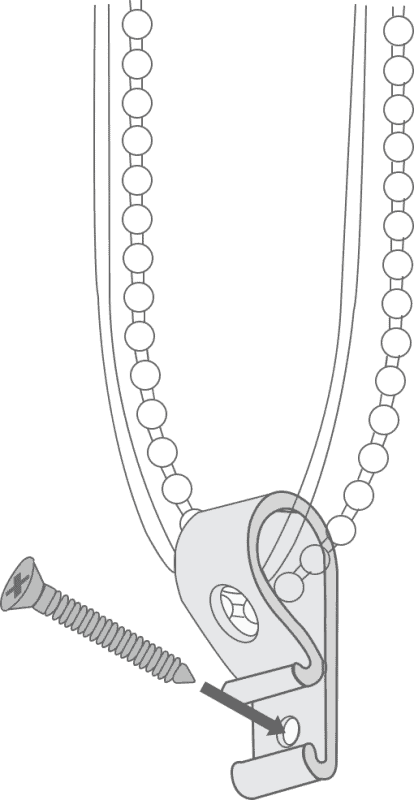

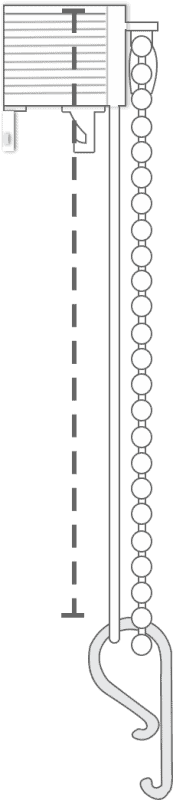

Cord Tensioner

Your vertical blind is fully compliant with the latest safety

standards. It has been supplied with a ‘P-Clip’ tensioning device

to keep the cords and the chain child safe.

Slot both the cord and the beaded chain into the ‘P-Clip’ and

secure it to the wall or window frame (if you are fixing to the

facing surface then the cord and chain will form a figure of

eight, this is fine and will not affect the operation of your blind).

Top Tip

Please note that the P-clip must be installed. The cord must be kept under tension to prevent it from sagging down from the headrail when the blind is drawn open.

Position the‘P-Clip’ at themaximumpossibledistance,ensuring thecord and chainare taut.

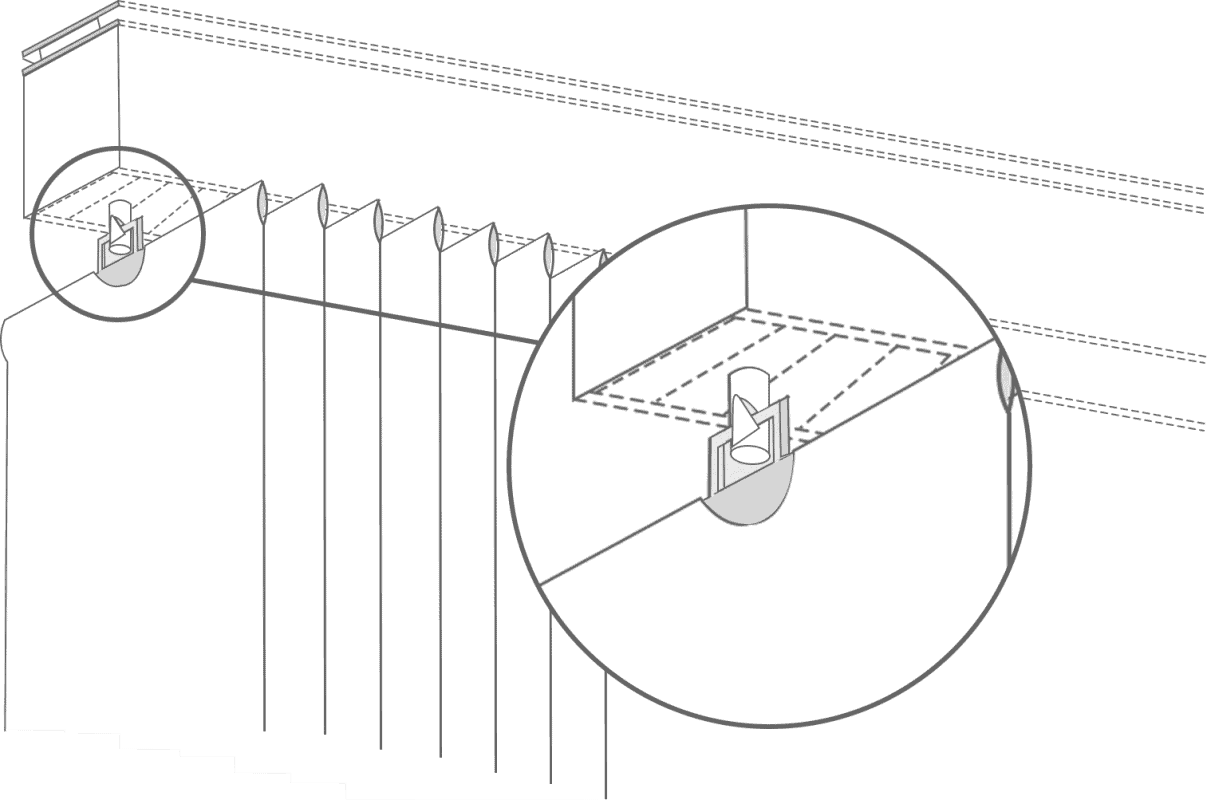

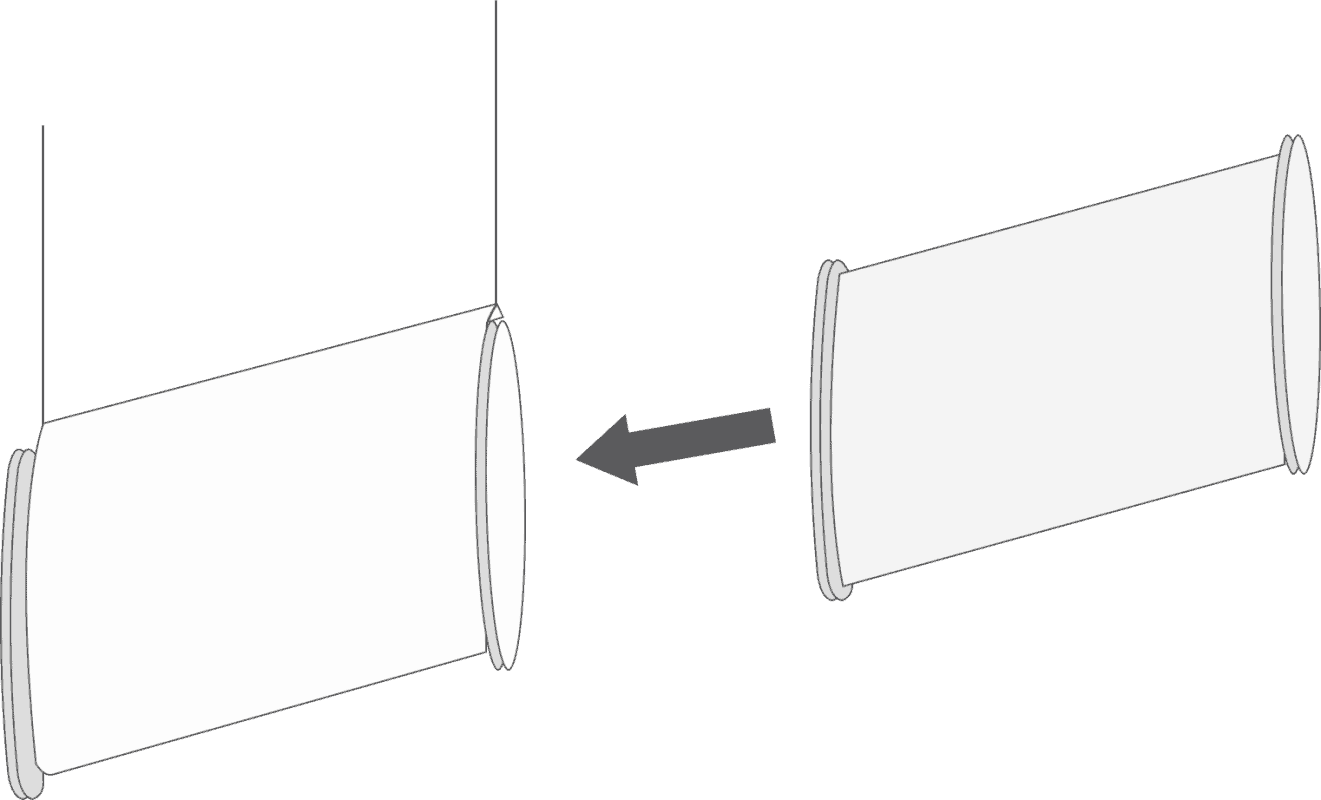

Hanging the louvres Step 4

Hook the louvres onto the rail.

Slide the weights into the pockets at the bottom of thelouvres.

Roller Blinds

Before you begin

We will have positioned the controls where you requested during the ordering process. However if you decide to swap the side that they are on, direction of the roll or need to trim the blind further, the controls can be removed by simply unplugging them from the tube. This should be done prior to fixing the brackets.

Fitting the brackets Step 1

The brackets offer three methods of installation:

Top-Fixing

Where the brackets are screwed into the lintel (or ‘ceiling’ of the recess)

Face-Fixing

Where the brackets are screwed onto a facing surface (a wall or window frame)

Side-Fixing

Where the brackets are screwed into the side walls of the recess

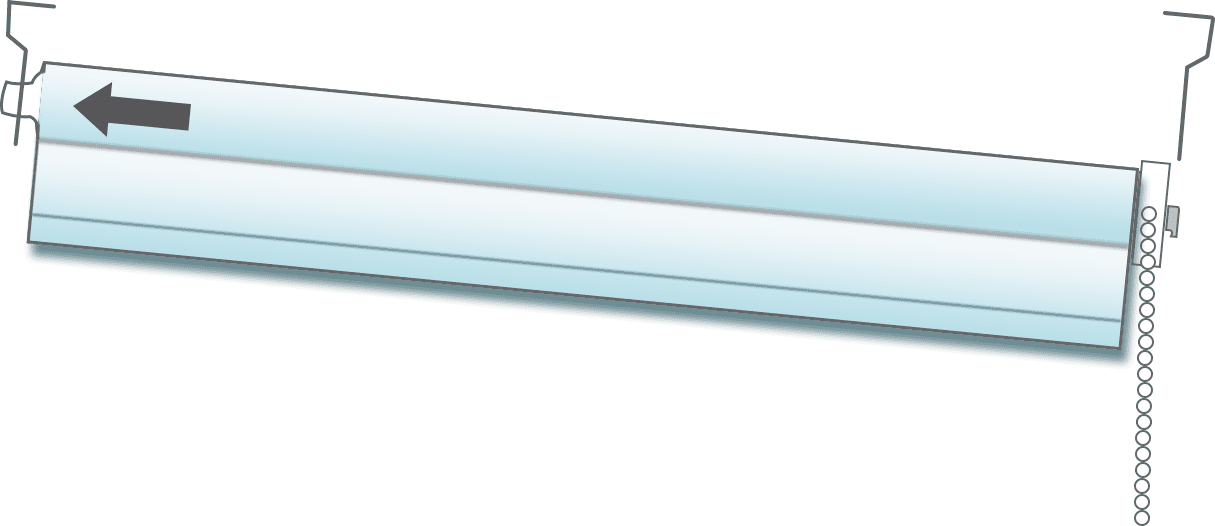

Fitting the blind Step 2

Locate the pin-end (the opposite end to the controls) of the blind into the central hole in the corresponding bracket.

Lift the control end of the blind and slot the rectangular ‘lugs’ into the corresponding slots on the bracket.

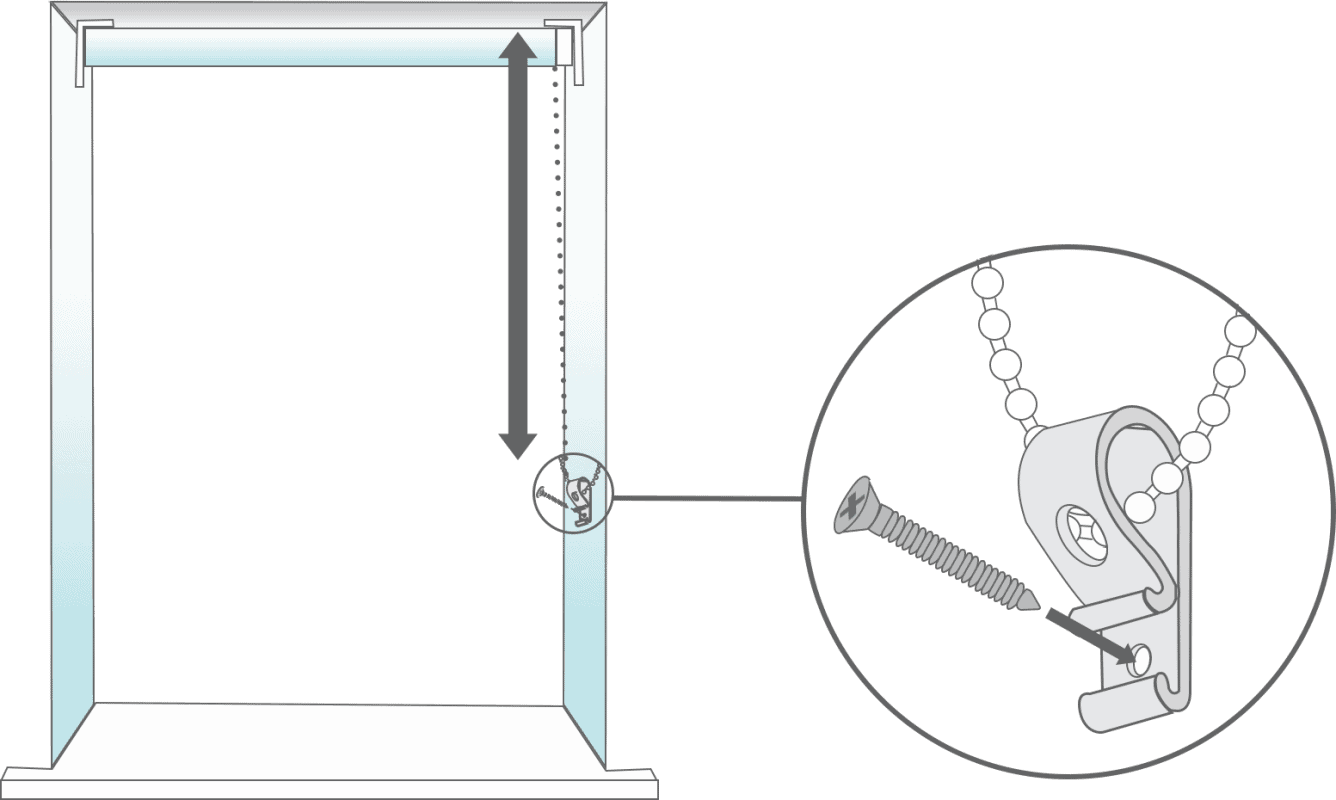

Child Safety Step 3

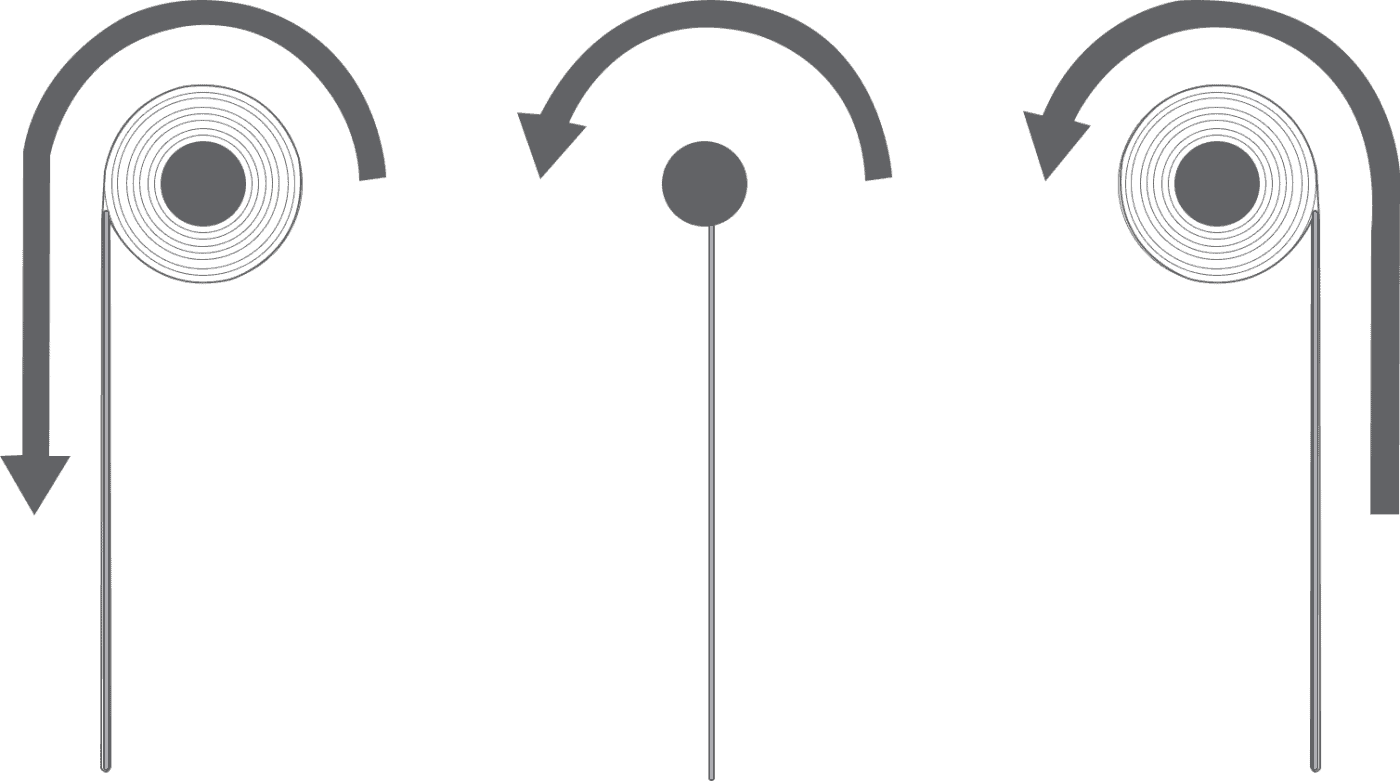

Cord Tensioner

The cord retaining device must be installed at the maximum distance possible from the control mechanism to prevent looped cords from becoming slack.

Place the retaining device on the wall and mark the position of the screw hole(s) with a pencil.

Attach the retaining device to the wall using the fixings provided.

Additional Information Step 4

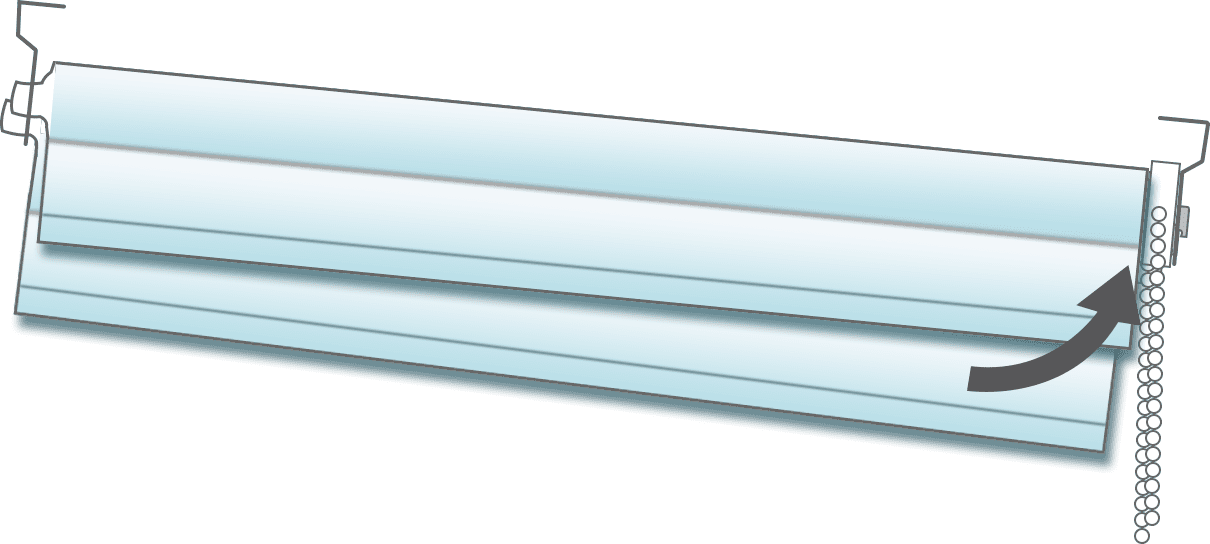

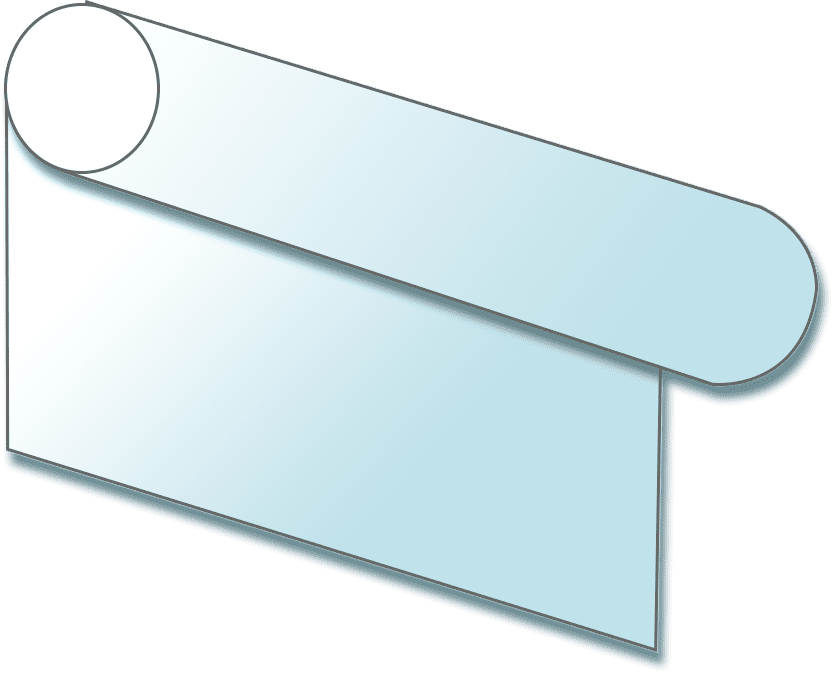

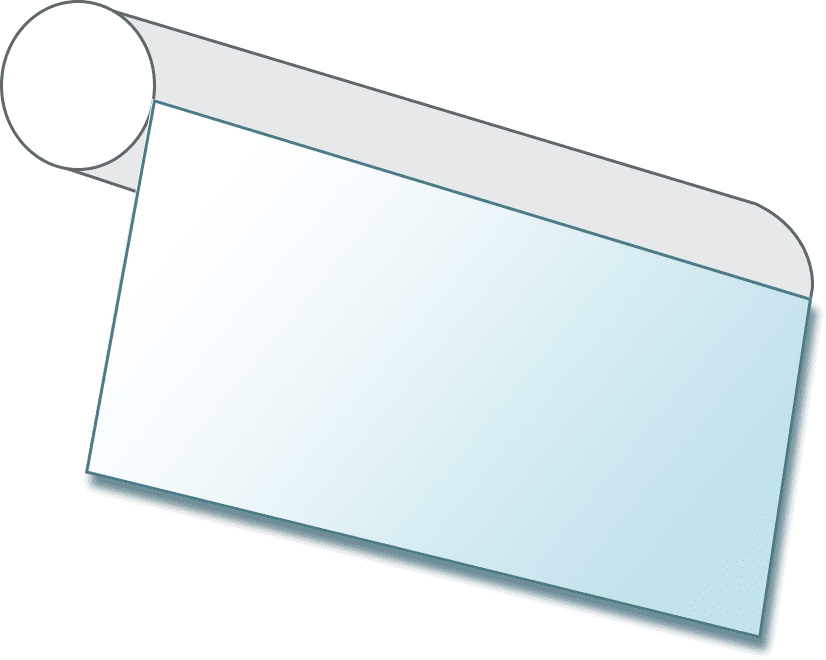

Reverse rolling the fabric

Standard

Roller blinds can have the fabric rolled onto the tube in two directions. The first is referred to as a ‘standard’ roll. This will place the fabric closest to the window or wall so that it comes down at the back of the tube. This is typically used with blackout blinds when they are mounted outside of a recess, the standard roll meaning that there is less light leakage.

Reverse

The second method is referred to as a ‘reverse’ roll, which places the fabric so that it comes down at the front of the tube, effectively hiding the roll. This method will allow clearance behind the fabric, for window handles and other obstructions, if you’re mounting the blind inside a recess.

If you wish to change the roll method then it’s easy; simply pull the back of the chain to lower the blind, and continue pulling until the metal tube is exposed. Keep going and the blind will begin to raise, with the fabric now rolling up over the front of the roller tube. Note that this will reverse the direction you must pull the chain for raising and lowering the blind (you’ll now use the front of the chain to lower and the back of the chain to raise).

Installation Guide

Faux-Wooden Blinds

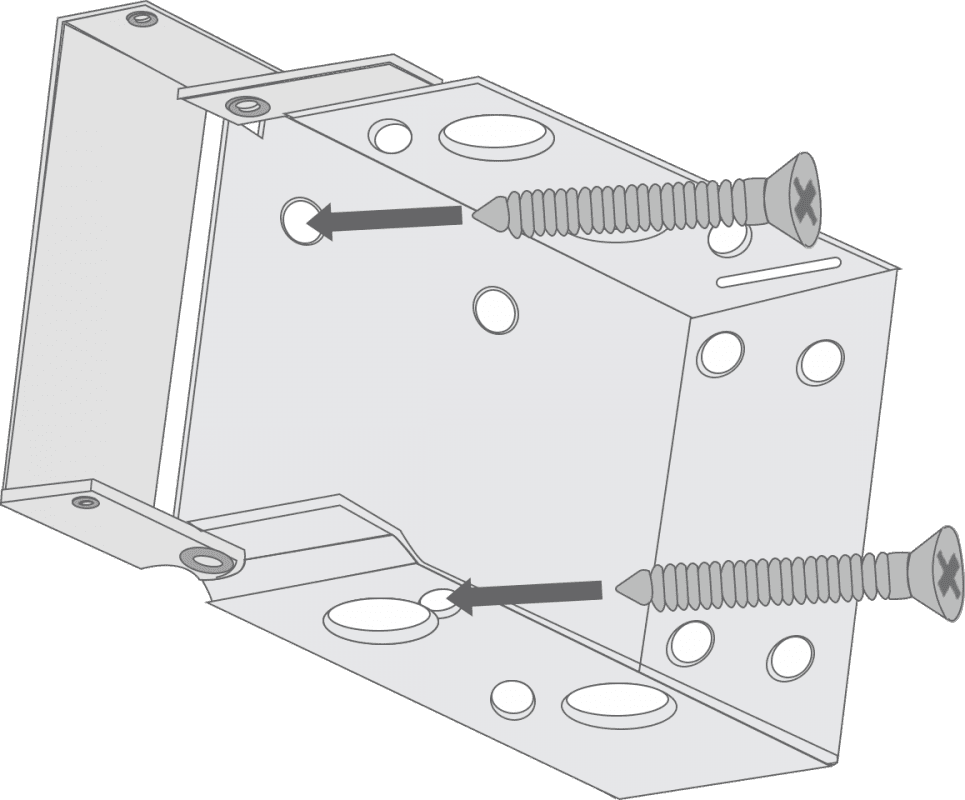

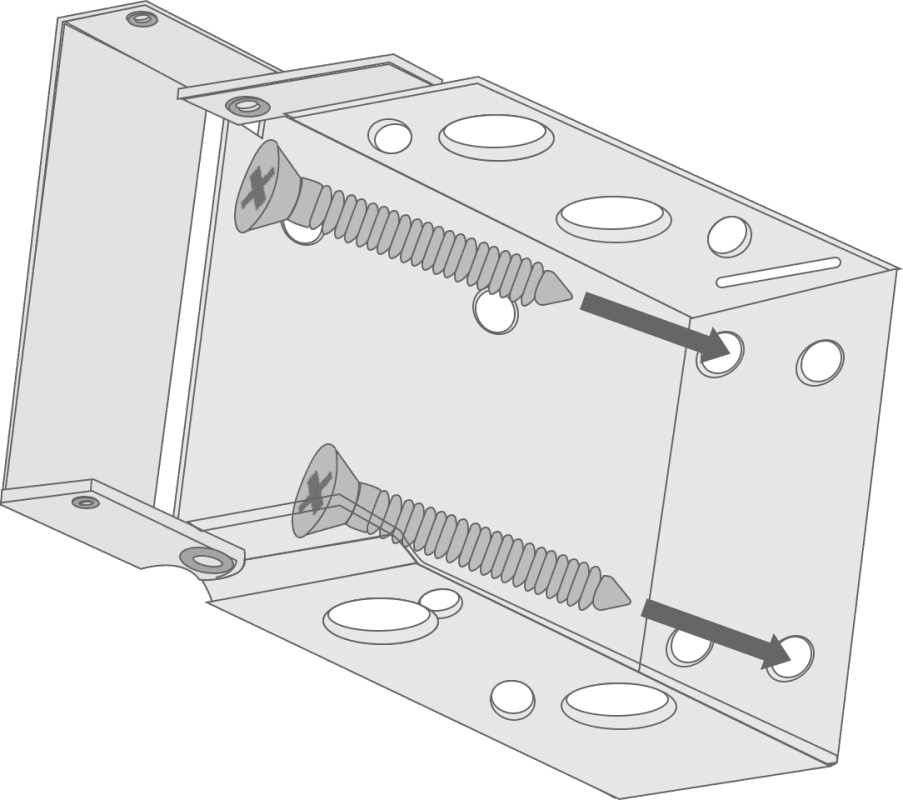

Fitting the brackets Step 1

The brackets offer three methods of installation:

Top-Fixing

Where the brackets are screwed into the lintel (or ‘ceiling’ of the recess)

Side-Fixing

Where the brackets are screwed into the side walls of the recess

Face-Fixing

Where the brackets are screwed onto a facing surface (a wall or window frame)

Top-Fixing

Face-Fixing

Wider blinds will be supplied with support brackets. These should be positioned towards the centre of the window area in-line with the box brackets. Make sure that the position of the support bracket is clear of any cords coming out of the headrail. Support brackets can be top-fixed or face-fixed.

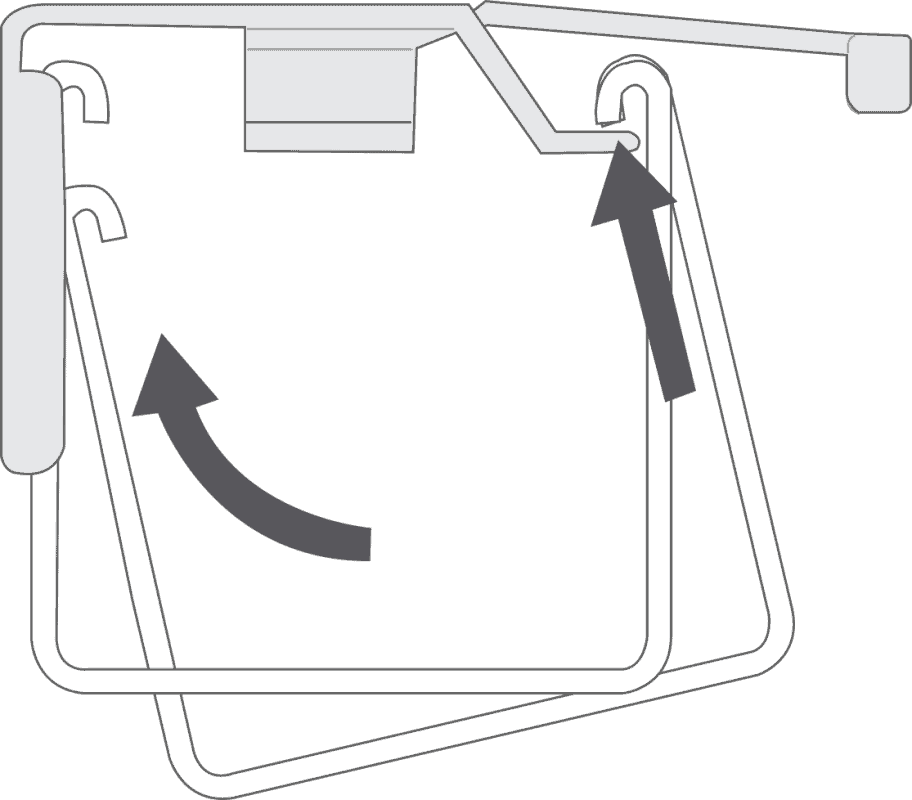

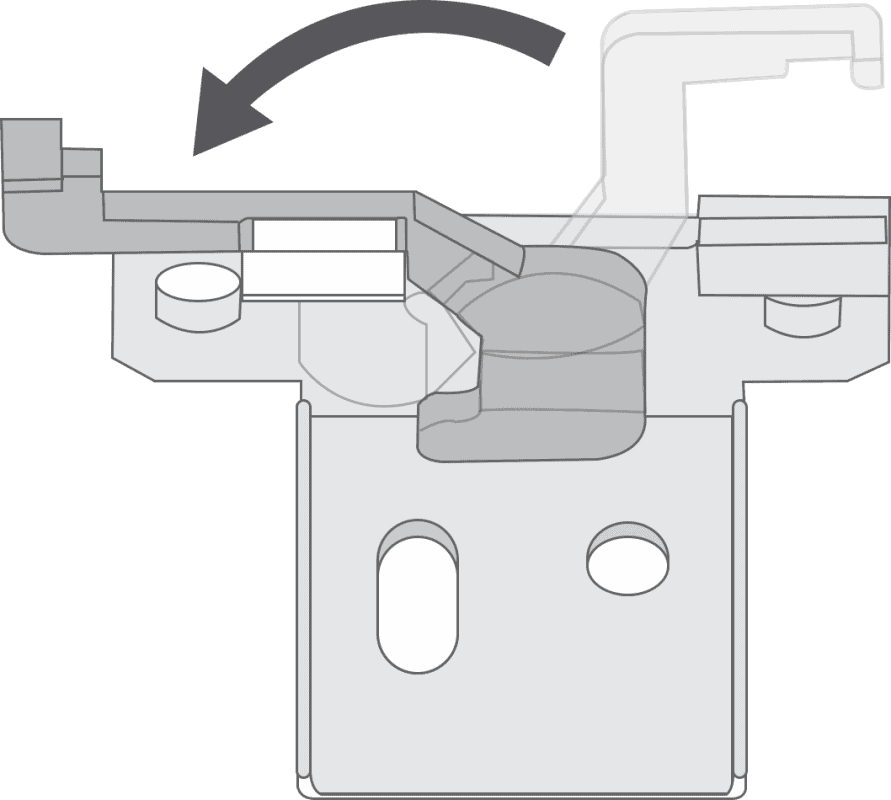

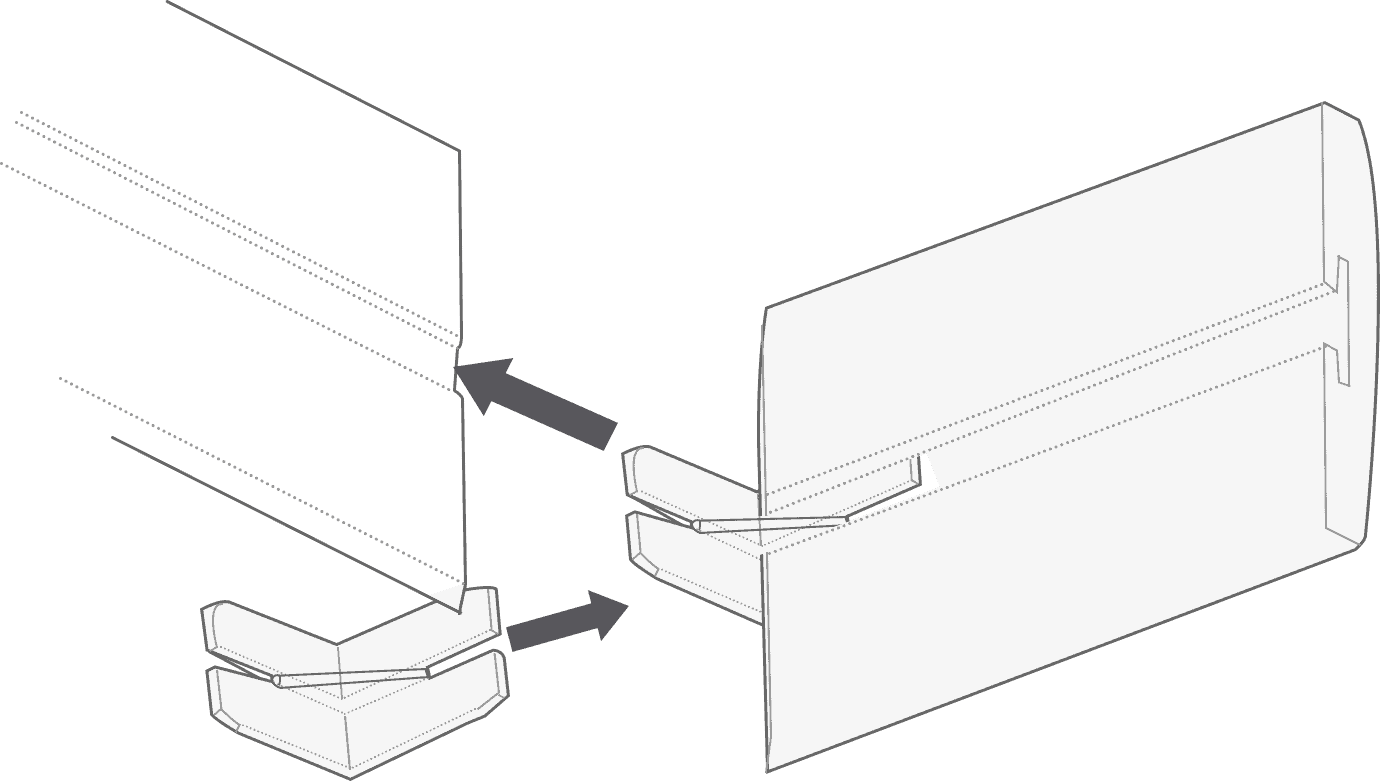

Fitting the blind Step 2

If you are fitting the blind inside a recess, go to step 3 before step 2.

Lift the blind to the window and slot the headrail into the open brackets. Swing the hinged section of the bracket closed and press firmly until it locks.

Attach the winged clips to the rear of the pelmet and hook the serrated pelmet clips onto the headrail (if installing the blind within a recess, this should be done before step 2) so that both the serrated clips and winged clips are in corresponding postions on the headrail and pelmet. Then align the two clips with each other and apply gentle pressure to the front of the pelmet, directly over the clips to click them together.

Fitting the pelmet Step 3

Pelmets for ‘Exact Fitting’

If you’ve ordered ‘exact fitting’ then the pelmet will be sent wider and mitred at the ends, with additional end returns to cover the brackets. Use the ‘L’ shaped plastic brackets from your fittings pack to attach the side returns to the pelmet.

Child Safety Step 4

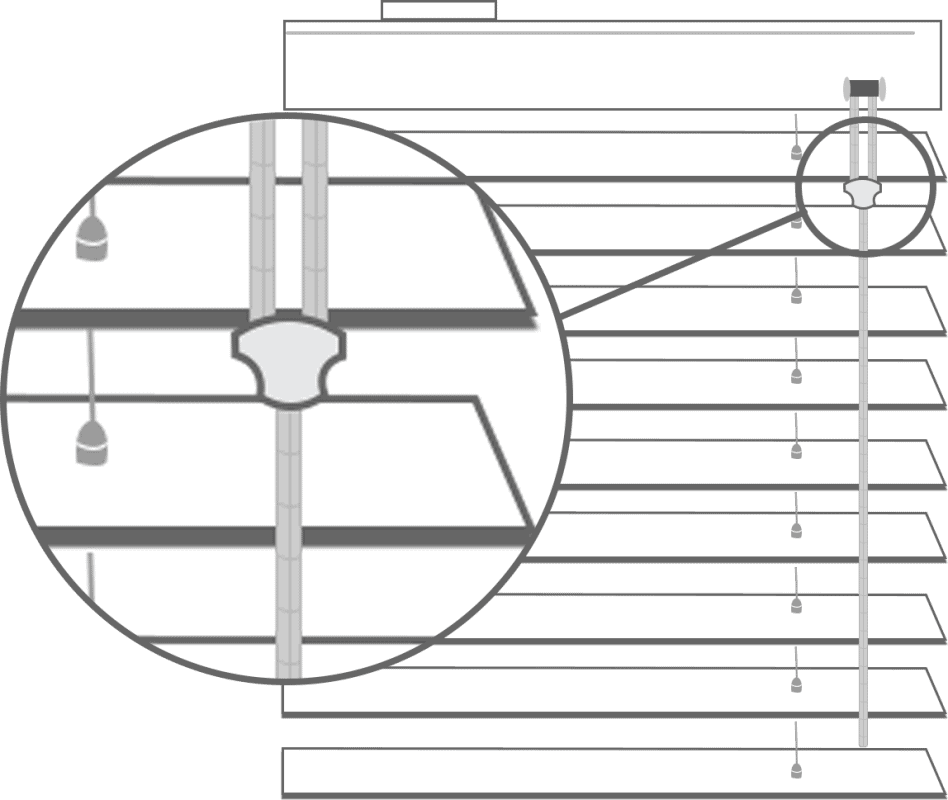

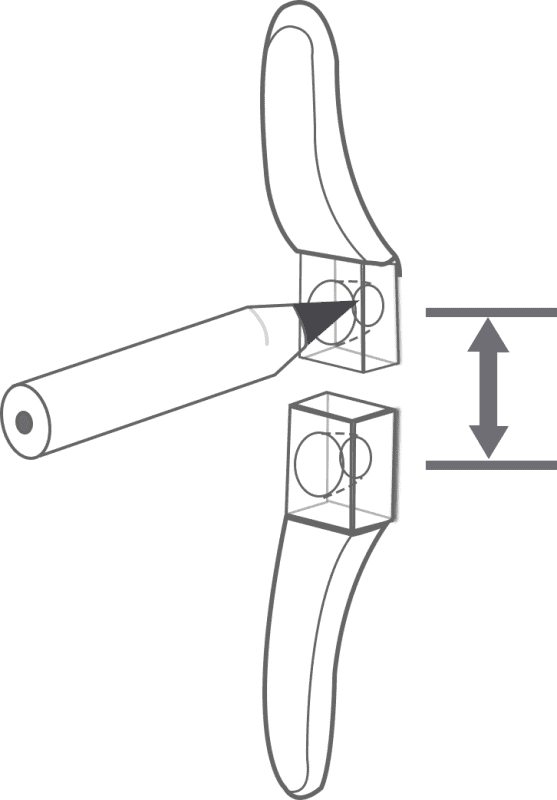

Cord Condenser

A breakaway cord condenser is pre-fitted to the lift cords so that when a horizontal force is applied to the cords above the condenser, it safely breaks away, eliminating any hazardous loops.

If the cord condenser is pulled apart:

Untwist the cords so that they’re nice and straight.

Slot the cords into the channel in the centre of one half of the consenser. If your condenser differs slightly from the diagram, don’t worry, just slot any cords that aren’t already tied into place inside in the same way.

Click the two halves back together, ensuring there is no loose thread trapped at the edges of the condenser.

Cord Safety Cleat

The safety cleat shall be installed as close to the headrail as possible and in all cases not less than 1500mm from the floor. The cord must be fully accumulated around the safety cleat(s) when the blind is not in use. Use the table below to determine the distance required between the cleats to fully accumulate the cords when the blind is fully raised.

| Drop of blind | *Distance between cord cleats(centre to centre) |

|---|---|

| 1-1000mm | 100mm |

| 1001-2000mm | 150mm |

| 2001-3000mm | 300mm |

Place the safety cleat in the desired position on the wall and mark the positions of the holes with a pencil.

*Distance between cord cleats(centre to centre)

Mark the hole positions and drill as required. Use the screws provided to attach the safety cleat to the wall.

Wrap the cords around the cord cleats in a figure of 8. When the cords are fully accumulated, ensure they are secure so that when any cord is pulled, no excess cord is released.

Shutter Installation

we are proud to be the leading supplier of Shutters and the vast majority of people are more than happy to purchase Shutters, after all we have built a business on this!

However we appreciate that whilst not difficult to measure and install, some people may lack the time or tools to install their

own interior Blind.

That’s why, Yourblind Shutters can provide one of our expert partners to come to your home to check your measurements and then install your interior shutters for you!

Curtain Installation

Pencil Pleat Curtains

Identify the left an right hand curtains ensuring that the join in the curtains in on the outer edge (fig 1).Tie the header tape cords on the inner edge of the curtain and pull the header tape cords from the outer edge evenly to create the pleats.Tie the header tape cords on the outer edge and secure behind the header tape, do not cut the header tape cords.Insert the hooks evenly along the header tape.If fitting to a curtain track use the middle or bottom pencil pleat tape (fig 2 B or C), if fitting to a curtain pole use the top pencil pleat tape (fig 2 A).Once both curtains have been gathered and hooks inserted, your curtains are ready to hang.

Pinch Pleat Curtains

Identify the left an right hand curtains ensuring that the join in the curtains in on the outer edge (fig 1).Pinch Pleat curtains will arrive with stab hooks already in position for fitting to a pole.If fitting to a track, you will need to re-align the hooks.Identify where the stab hooks need to be positioned so that the track is covered by the curtain, usually 9cm from the top of the curtain (fig 3).Ensure the stab hooks do not go through the face of the fabric when re-positioning.Your curtains are now ready to hang..

Eyelet Curtains

IIdentify the left an right hand curtains ensuring that the join in the curtains in on the outer edge (fig 1).Eyelet curtains are supplied secured in to pleats.Simply slide each curtain onto the pole ensuring the last eyelet is between the finial and the first bracket securing the pole.